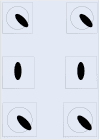

When you are deciding how to mount casters on your platform or equipment, there are many effective configurations.

The appropriate combination of swivel and fixed casters can provide great maneuverability, or a more inflexible ride depending on what you want.

Here are six standard designs for platforms, carts or equipment and a bit about what their unique applications.

In all cases it is necessary to ensure that the casters you choose have the required load capacity when combined together to carry the loads you intend to place on the cart or truck.

| Three Swivel Caster Design | |

|

With the minimum number of casters for a cart to work, this design is ideal for a dolly used to move barrels or for small portable machines. With all casters being a swivel design you have remarkable maneuverability to easily place your barrel or machine into position. The cart can also be a triangular shape if desired with the same results. One caution is that you need to calculate the caster capacity over three wheels rather than a standard four when determining the load capacity required of your casters. |

| Two Rigid / Two Swivel Caster Design | |

|

This is a very common caster design as it provides good maneuverability without making it difficult to keep the cart in a straight line when needed. This can be enhanced with casters that have a separate swivel lock, which can turn the cart into one that only moves in a straight line when desired. A great design for medium to heavy loads, especially if you need to move materials in a straight line. |

| Four Swivel Caster Design | |

|

This design is excellent when you need to move a machine or cart easily in both the forward and sideways direction. This allows you to pull a machine away from a wall, then travel sideways down a corridor, and return to an equivalent wall easily without the problems that could be caused by fixed casters.With swivel locks this cart can become equivalent to the two rigid / two swivel caster design discussed above. |

| Diamond Mounted Caster Design | |

|

This is a very maneuverable design that allows the cart or truck to turn on the center axis in order to make a complete turn in tight quarters. Meanwhile, you still have the rigid wheels placed so that you can easily travel longer distances without losing control of the steering.One drawback of this design is its limited usefulness on ramps as the uneven surface could cause tipping on the corners. |

| Tilt Mounted Caster Design | |

|

Tilt mounting occurs when the front and back casters are slightly smaller than the center casters (~1/8” difference tends to work well) which allows for better movement as you are only on three wheels at a time when moving and turning. Be cautious to choose casters with adequate load capacity as with the three swivel design.This caster combination also has the drawback of limited usefulness on ramps. |

| Four Swivel / Two Rigid Design | |

|

When looking for a design for heavy loads or longer trucks, using six casters can greatly increase your overall capacity. The center rigid casters help to distribute the weight and thus reduce the load on the swivel casters. This provides great maneuverability and easy steering much like the diamond mount.When the swivel casters are slightly smaller, such as in the tilt mounted caster design, you have the combination typically used on platform trucks. |

The Service and Knowledge You Need – No Matter How You Mount Your Casters

If you’re not sure what type of casters and wheels you need, or what configuration to use, Dougas Equipment is here to help. Contact us today and let our support team find you the casters and configuration best suited to your needs.